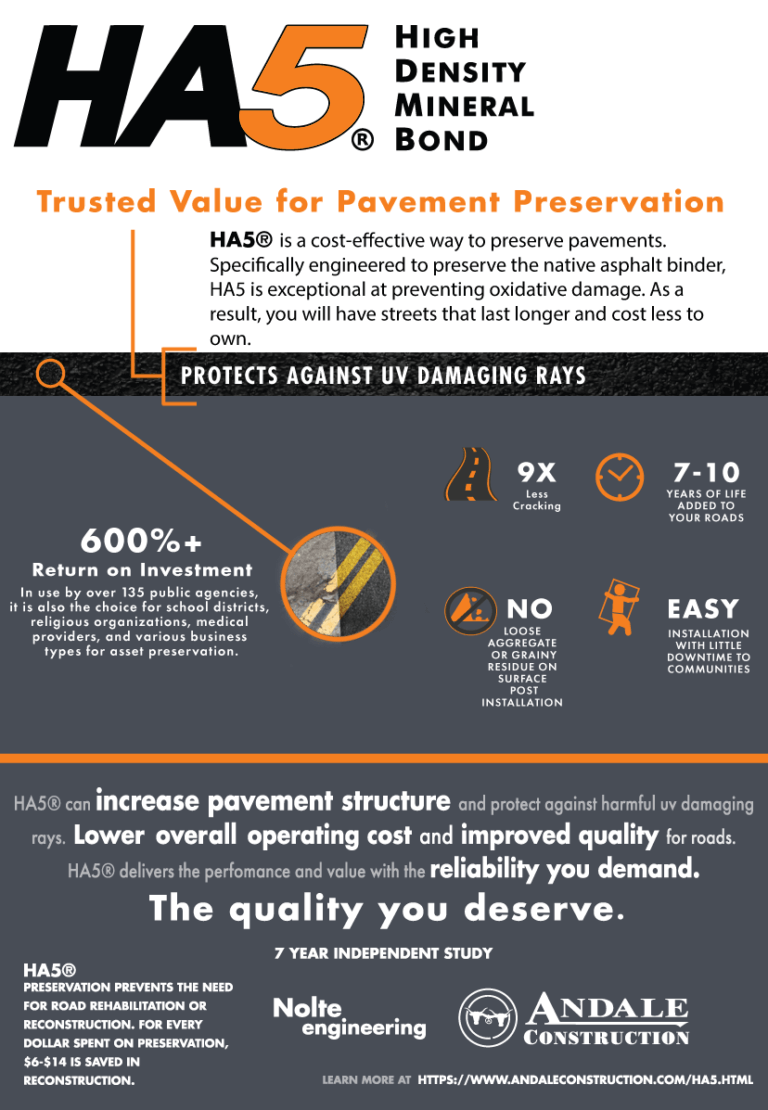

Extend Asphalt Serviceability with a High Density Mineral Bond Surface Treatment.

The Most Cost-Effective Strategy for Managing Asphalt Pavement

HA5® was developed to meet the demand for effective asphalt preservation on residential roadways without the negative side effects of chip seals or slurry seals. Specifically engineered to preserve the native asphalt binder, HA5 is exceptional at preventing oxidative damage. As a result, you will have streets that last longer and cost less to own.

A Preservation Treatment with a 600%+ Return on Investment

Due to the asset preservation qualities and durability of the installations, HA5 is also a surface treatment specified by owners and managers responsible for asphalt roads and parking surfaces. In use by over 135 public agencies, it is also the choice for school districts, religious organizations, medical providers, and various business types for asset preservation.

- Significantly extends pavement life

- Lower cost of pavement ownership/management

- Performance backed by seven year study

- Millions of square feet installed by municipalities

- High Public approval rating

- Faster installation

What is HA5?

HA5 is a High Density Mineral Bond uniquely emulsified with a near neutral charge that is able to hold a proprietary blend of fine aggregates. Limiting oxidative damage from moisture is fundamental to HA5’s preservation qualities. But just as critical to the prevention of oxidative damage from moisture is preventing oxidative damage from Ultraviolet (UV) radiation. HA5 combats oxidation from UV by including limited amounts of specific polymers to reflect damaging UV rays.

Installation

Fast Installation

For HA5 to be properly installed, specialized equipment is required that can uniformly disperse a thixotropic material housing the required density of fine aggregate.Tested, Proven Performance

Independently Tested

HA5 has been independently evaluated by Nolte Engineering and was recommend as a superior option to slurry seals on residential (lower load/volume) roadways and parking surfaces.You need to

9X Less Cracking

People like black roads, but simply turning a road black does not necessarily equate to effectively extending the useful life of asphalt pavement. Six years ago, an evaluation was completed comparing HA5’s performance in a side-by-side comparison with another treatment. On one section, a commercially available polymer-enhanced asphalt emulsion was installed within a week of an adjoining HA5 installation. The original paving of both sections was done as one project nine years before the side-by-side maintenance treatments were installed. Each of the treated sections had multiple crack samples taken. The HA5 treated section had sample areas examined that calculated to an average .007 of the surface experiencing cracking and the polymer enhanced asphalt emulsion sampled road surface was found to have .06 of the area with cracking. That’s an astounding 857% more cracking in the non-HA5 treated pavement compared to the road having had HA5 installed.

© Copyright Andale Construction Inc. All rights reserved